Fuel and ignition calculations. More...

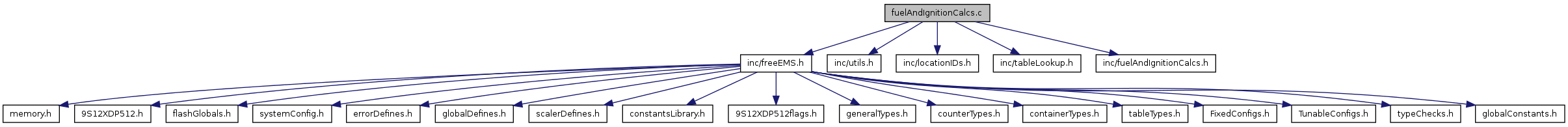

#include "inc/freeEMS.h"#include "inc/utils.h"#include "inc/locationIDs.h"#include "inc/tableLookup.h"#include "inc/fuelAndIgnitionCalcs.h"

Go to the source code of this file.

Macros | |

| #define | FUELANDIGNITIONCALCS_C |

Functions | |

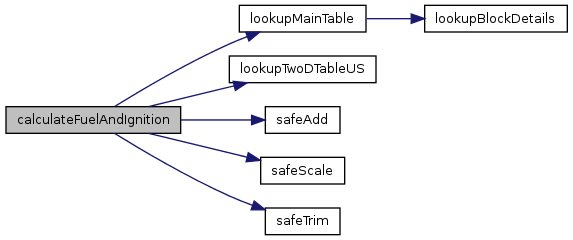

| void | calculateFuelAndIgnition () |

| Final fuel and ignition calculations. | |

Detailed Description

Fuel and ignition calculations.

This file contains all of the main fuel and ignition calculations based upon the variables that we have already determined in previous stages.

Definition in file fuelAndIgnitionCalcs.c.

Macro Definition Documentation

| #define FUELANDIGNITIONCALCS_C |

Definition at line 38 of file fuelAndIgnitionCalcs.c.

Function Documentation

| void calculateFuelAndIgnition | ( | void | ) |

Final fuel and ignition calculations.

Using a variety of primary algorithms calculate a base pulsewidth and then apply various corrections to it such as injector dead time, transient fuel correction, engine temperature enrichment and per cylinder trims. The ignition timing and fuel injection timing are also determined here, as are the various limiters and cuts.

- Todo:

- TODO figure out what the correct "temperature" is to make MAF work correctly!

- Todo:

- accumulate errors such that we know what sort of PW WOULD have been requested and enable a "over duty cut" to protect boosted users with insufficient injector size on cold nights

TODO

- Todo:

- FIXME part of to schedule or not to schedule should be : (masterPulseWidth > injectorMinimumPulseWidth)

Definition at line 53 of file fuelAndIgnitionCalcs.c.

References DerivedVar::AirFlow, AirflowTableLocationID, ALGO_ALPHA_N, ALGO_MAF, ALGO_SD_AN_BLEND, fixedConfig2::algorithmSettings, algorithmSetting::algorithmType, KeyUserDebug::alphaNAirFlow, DerivedVar::BasePW, KeyUserDebug::blendAlphaNPercent, bootFuelConst, CoreVars, fixedConfig1::cutAndLimiterSettings, cutAndLimiterSetting::cutsEnabled, DEGREES_C, DerivedVar::densityAndFuel, engineSetting::densityOfFuelAtSTP, DerivedVars, singleCut::disableThreshold, DerivedVar::EffectivePW, fixedConfig1::engineSettings, DerivedVar::ETE, fixedConfigs1, fixedConfigs2, FUEL_DENSITY, FUEL_DENSITY_UNIT_FACTOR, CoreVar::IAT, DerivedVar::IDT, KeyUserDebug::ignitionCuts, cutEnabled::IgnitionRPM, cutAndLimiterSetting::IgnitionRPM, cutEnabled::IgnOverBoost, KeyUserDebug::injectionCuts, cutEnabled::InjectionRPM, cutAndLimiterSetting::InjectionRPM, cutEnabled::InjOverBoost, KeyUserDebugs, LAMBDA, DerivedVar::Lambda, lookupMainTable(), lookupTwoDTableUS(), CoreVar::MAF, CoreVar::MAP, masterPulseWidth, schedulingSetting::numberOfInjectionsPerEngineCycle, cutAndLimiterSetting::OverBoost, singleCut::reenableThreshold, DerivedVar::RefPW, CoreVar::RPM, safeAdd(), safeScale(), safeTrim(), fixedConfig1::schedulingSettings, SHORT4TH, SHORTMAX, KeyUserDebug::speedDensityAirFlow, DerivedVar::TFCTotal, CoreVar::TPS, VE, DerivedVar::VEMain, and VETableMainLocationID.

Referenced by main().

1.8.1.2

1.8.1.2