Go to the source code of this file.

Macros | |

| #define | EXTERN extern |

Functions | |

| void | scheduleOutputs (void) FPAGE_FE |

| Precision timed output scheduling. | |

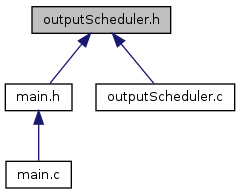

Detailed Description

Definition in file outputScheduler.h.

Macro Definition Documentation

| #define EXTERN extern |

Definition at line 48 of file outputScheduler.h.

Function Documentation

| void scheduleOutputs | ( | void | ) |

Precision timed output scheduling.

Calculates which input tooth and post tooth delay any given event should used based on the configuration provided.

TODO

- Todo:

- FIXME part of to schedule or not to schedule should be : (masterPulseWidth > injectorMinimumPulseWidth)

- Todo:

- don't bother doing anything, settings don't make sense... TODO move this to init time to prevent bad config

- Todo:

- don't bother doing anything, settings don't make sense... TODO move this to init time to prevent bad config

- Todo:

- TODO create this check:

- Todo:

- TODO Schedule injection with real timing, requires some tweaks to work right.

- Todo:

- TODO move this loop variable to fixedConfig and make a subset of the remainder of channels configured for fuel with a start time/tooth directly set for now, ie, make the 6 channels usable as fuel or ignition from reasonable configuration and write a guide on how to set it up for any engine.

- Todo:

- TODO move sched code to a function or functions (inline?) that can be unit tested such that we KNOW it performs as anticipated rather than just trying it out on a 400hp turbo truck engine.

- Todo:

- TODO keep an eye on overflow here when increasing resolution by scaling angles

- Todo:

- TODO, do this ^ at init time from fixed config as an array of angles and a single engine offset combined into this runtime array.

- Todo:

- TODO rather than look for the nearest tooth and then step through till you find the right one that can work, instead figure out the dwell in angle and subtract that too, and find the correct tooth first time, will save cpu cycles, and get same answer and be less complex...

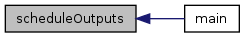

Definition at line 48 of file outputScheduler.c.

References DerivedVar::Advance, schedulingSetting::anglesOfTDC, ATOMIC_END, ATOMIC_START, CoreVars, Counters, schedulingSetting::decoderEngineOffset, decoderMaxCodeTime, DerivedVars, DerivedVar::Dwell, ectSwitchOnCodeTime, eventAngles, fixedConfigs1, KeyUserDebug::ignitionCuts, KeyUserDebug::injectionCuts, KeyUserDebugs, LONGMAX, masterPulseWidth, MAX_NUMBER_OF_OUTPUT_EVENTS, schedulingSetting::numberOfConfiguredOutputEvents, numberOfRealEvents, numberOfVirtualEvents, ONES, outputEventDelayFinalPeriod, outputEventDelayTotalPeriod, outputEventExtendNumberOfRepeats, outputEventExtendRepeatPeriod, outputEventInputEventNumbers, outputEventPulseWidthsMath, CoreVar::RPM, schedulingSetting::schedulingConfigurationBits, fixedConfig1::schedulingSettings, SHORTMAX, skipEventFlags, ticks_per_degree_multiplier, ticksPerDegree, Counter::timerStretchedToSchedule, and totalEventAngleRange.

Referenced by main().

1.8.1.2

1.8.1.2